Home > Innovation and Tech > How Can 3D-Printed Braces Relieve Chronic Pain?

3D printing, also known as additive manufacturing, creates three-dimensional objects by depositing materials layer by layer based on a digital design. The object is created by adding successive layers of material until the whole object is formed.

The process usually begins with a 3D digital model created using computer-aided design (CAD) software. This virtual model is then cut into thin cross-sectional layers, which the 3D printer reads to build the object layer by layer. The printer uses a variety of materials, including plastics, metals, ceramics, resins, and even food ingredients, depending on the type of printer and its capabilities.

3D printing offers many advantages, including the ability to create complex geometries and intricate details that may be difficult, if not impossible, to achieve with traditional manufacturing methods. It enables rapid prototyping, customization, and on-demand manufacturing, as objects can be produced quickly and efficiently without the need for complex tools or molds.

Current applications of 3D printing cover a wide range of industries. It is used in product design and development, architecture, automotive and aerospace manufacturing, healthcare (such as the creation of medical implants or orthotics), and many other fields. 3D printing has revolutionized the manufacturing landscape, offering new opportunities for design, production, and innovation and a more flexible and responsive supply chain.

3D printing has brought important innovations to many fields, including healthcare, in the manufacturing of pharmaceuticals, artificial organs, tissues, and orthotics.

3D printing has revolutionized manufacturing of orthotics by enabling the creation of custom-made orthotics that are affordable and readily available. Here is how 3D printing is used in orthotics:

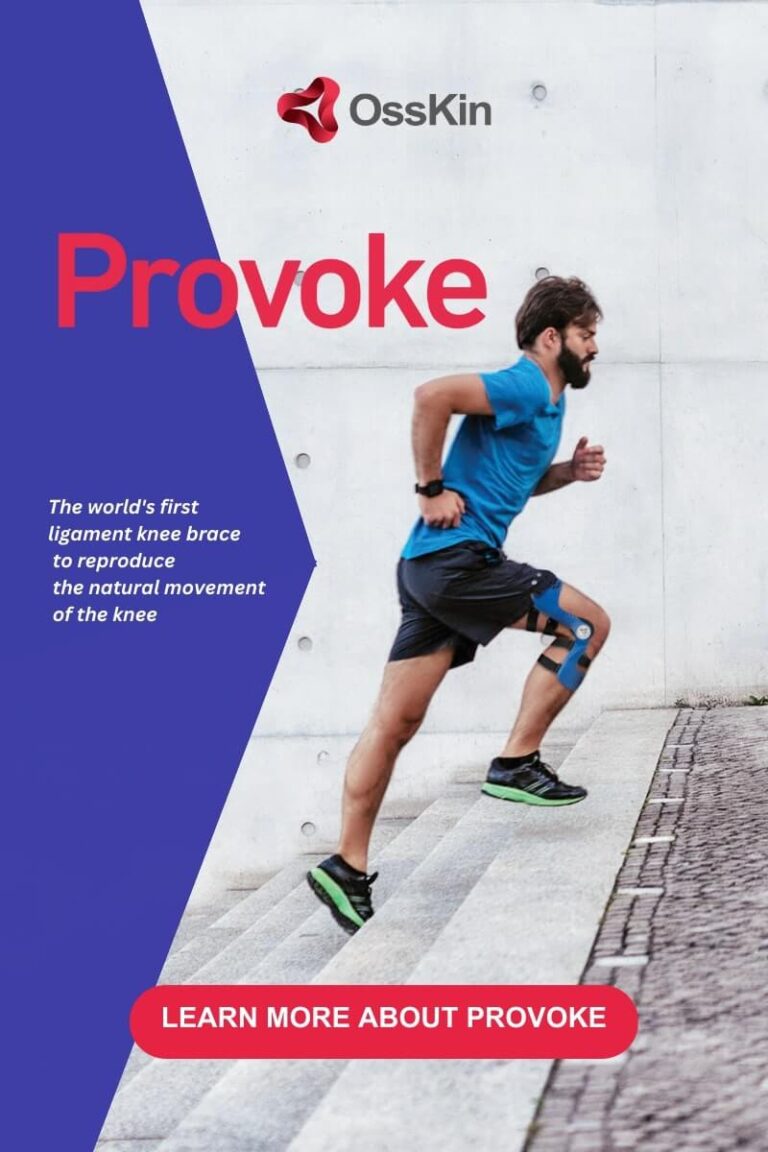

Evoke knee braces and Provoke knee braces by OssKin are fully 3D-printed, based on measurements taken on each patient’s leg by the clinician to perfectly match their morphology.

Using landmarks, the clinician can quickly scan the patient’s leg using a tablet. This scan will enable precise measurements to be taken, saving time for the clinician, who previously had to use plaster to obtain a mold.

These measurements will then be sent to OssKin, which will use its software to propose a customized orthotic design, unique to each patient.

OssKin orthoses offer unobtrusive protection for the knee structure.

By applying compression during 3D modeling, the perfect fit of the brace eliminates any discrepancy between the leg and the brace that may otherwise create gapping.

With 3D modeling and Provoke’s anterior tibial cuff design, Provoke conforms to the triangular anterior shape of the tibialis, thus obtaining a better grasp and control of the tibia.

One of the main problems encountered by clinicians is that patients do not wear their traditional orthotic over time due to the discomfort and weight.

The OssKin customized orthosis combats this by reducing migration and providing better support for patients. Thanks to 3D printing, the orthosis, made from polyamide 2200, is lighter than traditional orthoses. As a result, patients can wear their orthoses more comfortably and consistently to relieve chronic knee pain. The thinness of OssKin orthoses also allow patients to wear their orthoses on both knees without friction between the two.

OssKin has the best custom knee brace orthoses that offer a real treatment plan because of the patented Asymmotion™ helical hinge system, which reproduces the knee’s natural three-dimensional kinematics. This unique mechanism replicates internal and external rotation, abduction, and adduction, as well as anteroposterior and vertical displacements in the knee. The fluidity of the natural motion can help to offload other joints that may have been compensating for the knee pain and reduce aches in these joints as well.

Share on

OssKin © 2024